Scientists at the Institut für Integrierte Produktion Hannover (IPH) gGmbH and the Laser Zentrum Hannover e.V. (LZH), are working on a new project that aims at welding 3D-printed components with laser. In the new research project “QualLa“, they want to develop an expert system that supports small and medium-sized enterprises in optimizing additive manufacturing processes – so that the printed components can subsequently be welded soundly with the laser.

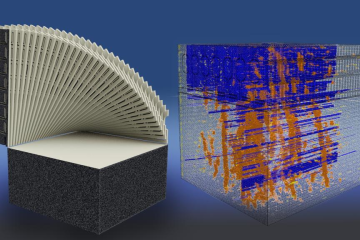

For injection-molded plastic components, laser transmission welding is already an established industrial joining process. For components from the 3D printer, however, the joining does not yet work because cavities and boundary layers in the 3D-printed components prevent a uniform weld. These cavities and boundary layers are individual to each component because, in additive manufacturing, no two components are alike. Even components from the same series are only identical on the outside; the internal structure can be different.

To enable small and medium-sized enterprises (SMEs) to weld 3D-printed plastic components with lasers without analyzing each component in detail in advance, the IPH and LZH scientists want to develop an expert system and bundle process knowledge in this computer program.

In the project “Quality assurance in laser welding of additively manufactured thermoplastic components (QualLa)“, the researchers are looking at fused deposition modeling (FDM) for this purpose. In this additive process, thin strands of molten plastic are superimposed layer by layer.

Even before the 3D printing process starts, the expert system is supposed to provide recommendations on which material, which layer thickness, and which layer orientation are best suited to achieve the highest possible transmission – in other words, the highest possible permeability for the laser beam. Thanks to this preliminary work, it will be possible to weld the printed components optimally afterward.

In addition, the scientists want to develop a method to measure the transmission with spatial resolution. This involves determining for an individual component at which points the laser beam is transmitted and to what extent. This data will then be used to control the laser transmission welding process with the help of the expert system.

If the laser beam is less transmitted at a certain point, the laser power must be increased. If the component is more light-transmissive at another point, lower laser power is sufficient. The researchers’ goal is to develop a process control system that adjusts the laser power as a function of transmission so that a uniform weld seam is produced – even if the 3D-printed component does not transmit the laser beam uniformly.

The scientists want to use machine learning methods to process the information. The plan is to use neural networks, a type of artificial intelligence that makes the expert system capable of learning. The system will learn to recognize correlations between various input variables and the print result independently and thus predict the expected transmission.

Laser transmission welding can be used to join components made of thermoplastics – contact-free, automatable, without mechanical, and with low thermal stress. Two joining partners – one made of transparent, one of non-transparent plastic – are welded to each other with a laser beam. The laser beam penetrates the transparent joining partner, and as soon as it hits the non-transparent plastic, the laser light is absorbed and converted into thermal energy. As a result, the plastic in the joining area melts, and a weld seam is created.

IPH and LZH are working closely with the industry on the research project. The committee accompanying the project includes companies from the fields of laser technology, additive manufacturing and plant engineering. Other companies are welcome to participate in the project – companies involved in artificial intelligence or additive manufacturing are particularly sought after.